LED Upgrade Genuine Sencon Upgrades For Can Body Light Testers

Call us at: +1 (252) 220-8829

PRODUCT DESCRIPTION

Description: Upgrades For Can Body Light Testers, LED Upgrade for ULTP Systems – Three LED illuminator banks

Condition: New

Brand: Sencon

Part Number: LED Upgrade

Other OEM Part Numbers That Will Work: 706008AT

Included:

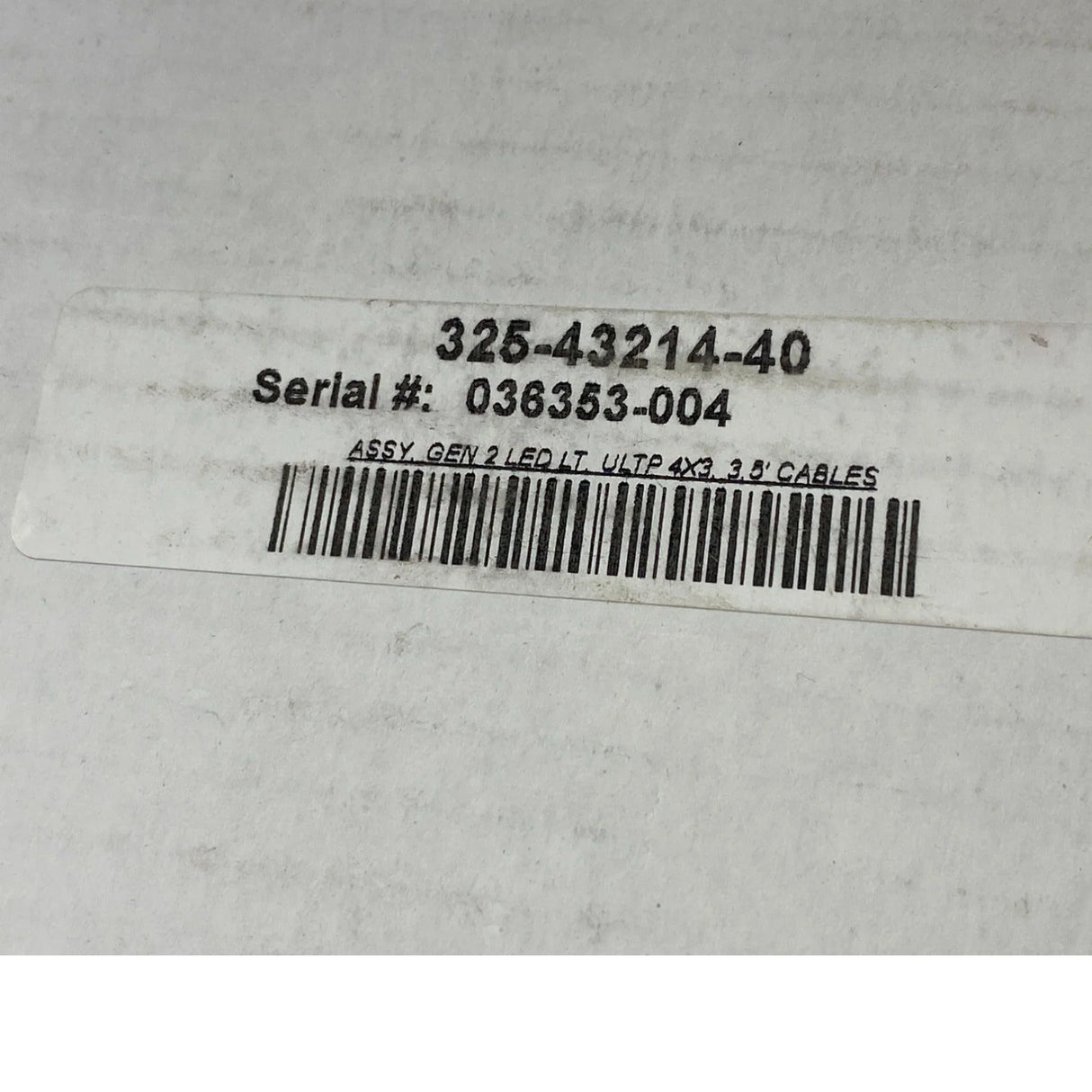

- 325-43214-40 Genuine Sencon Led Light Sensor Gen 2 Assembly

- 325-50502-21 Genuine Sencon Detector Head

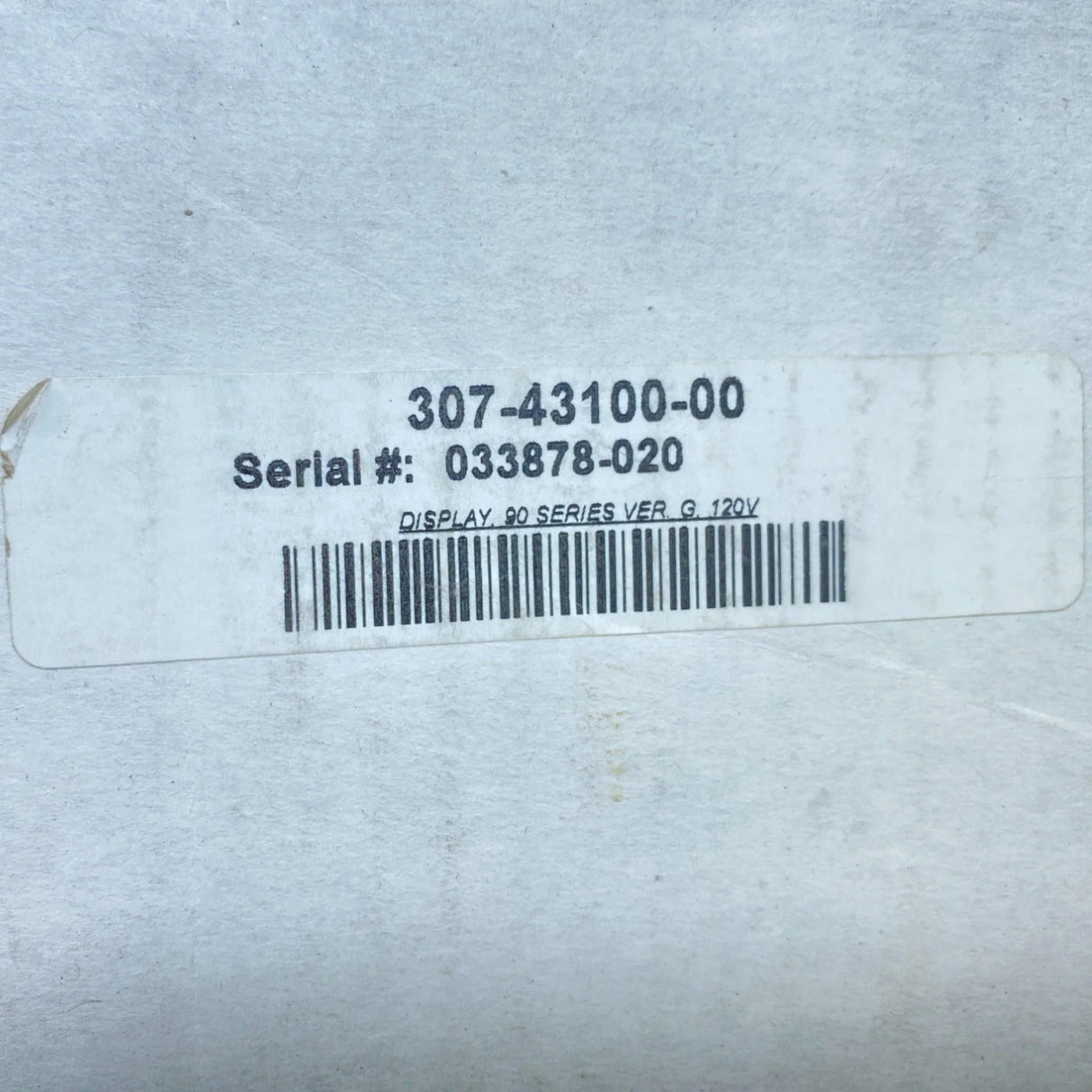

- 90-9002G3-120 Genuine Sencon Alphanumeric Display

- PBA1000F-48 Genuine Cosel Power Supply Module

- T-MDS1451-48HG Oriental Motor Axial Flow Fan

Details:

-Sencon light testers, which are commonly supplied on all the latest neckers, provide high speed light detection of pinholes, split flanges and cracked domes. Rejection rates of 100% are achieved on cans with 0.002 inch (50 microns) pinholes.

- Improved reliability and stability

- No degradation of sensitivity over time (single solid state electronic detector)

- Reduced maintenance and running costs

- Increased speed capability - 3600cpm

- Improved machine information

- Fault diagnostic facilities

- All kinds of cans accepted, including bottle cans

UPDATES FOR SINGLE DETECTOR CAN LIGHT TESTERS

Analog photomultipliers are prone to degrade over time, requiring constant adjustment or regular replacement. Photomultipliers are found on some single detector light testers (such as Reynolds RT5 or RT6*). Sencon can replace them with a solid state electronics pack and a simplified lighting system. This delivers greater stability with equivalent detection levels and no need for regular adjustments as the light detector does not become less sensitive over time. Maintenance is minimized as lamp replacement and cleaning of the detector lens are the only scheduled tasks. Existing quartz-halogen systems can be upgraded with an LED lighting array and a more sophisticated detector system.

- Improved system sensitivity to find smaller defects.

- Energy usage for the lamps is reduced by 30%

- Flash ControlTM to avoid the sensor being swamped by excess light from a defective can. (On non-LED systems three cans are rejected while the sensor recovers).

- No need for the can infeed lamp. Built in reflectors ensure the illumination is evenly distributed around the can.

LED UPGRADE

High intensity halogen lamps, which are supplied as standard on older installations, have proved to be simple and reliable. However, LEDs are better matched to the sensitivity of the detectors than broad spectrum halogen light. Installing an LED lighting array improves the sensitivity of the system. Using solid state LED lighting should also reduce the frequency of maintenance required, further minimizing downtime.

Built in reflectors ensure that illumination is evenly distributed around the can, removing any need for an infeed lamp. The LED lighting array is available in 3x3 or 3x4 configuration, which allows greater flexibility with different can sizes.

The LED upgrade requires the host ULTP system to be brought up to the latest specification. For most systems this represents a major overhaul, including:

- New illuminator housing

- Three LED illuminator banks with

- All kinds of can accepted, including bottle cans

- New detector head, matched to the LED light source

- New 'Flash Control' capability prevents detectors from being temporarily blinded by gross leakers

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.